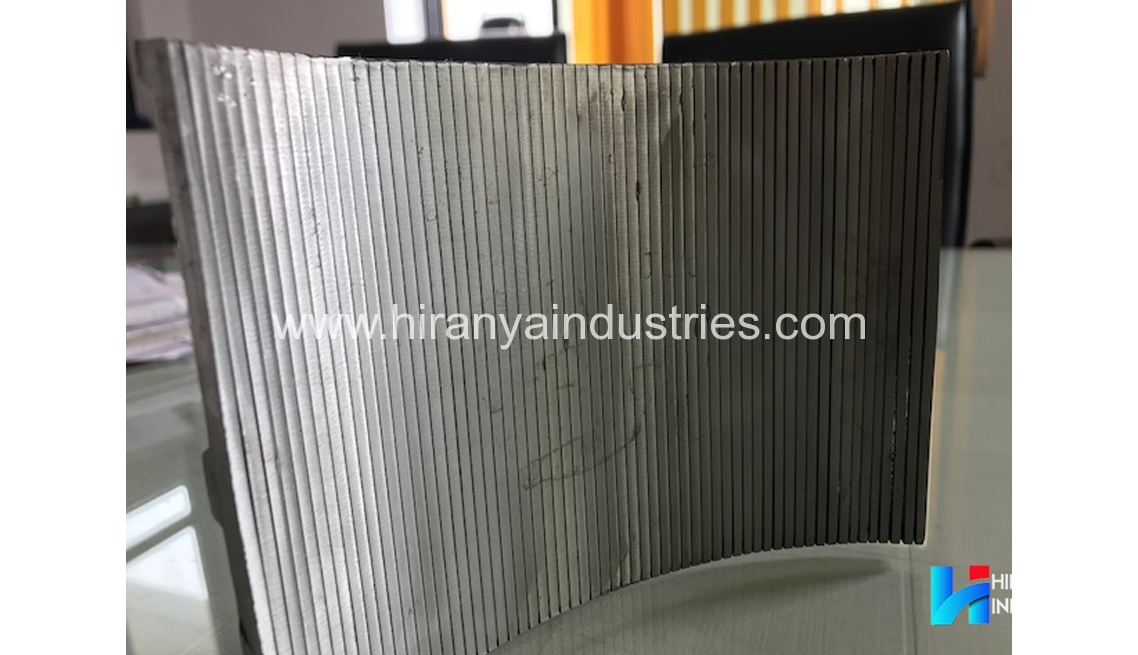

Slotted / Mild Steel Wedge Wire Screens

Mild screen are use when sticky production materials in centrifuge machinery .Mild screen give a be a centrifuge basket, DSM Screen, Conical basket & Rotary Screen in mild screenest results better than another welded wedge wire screen for sticky materials.

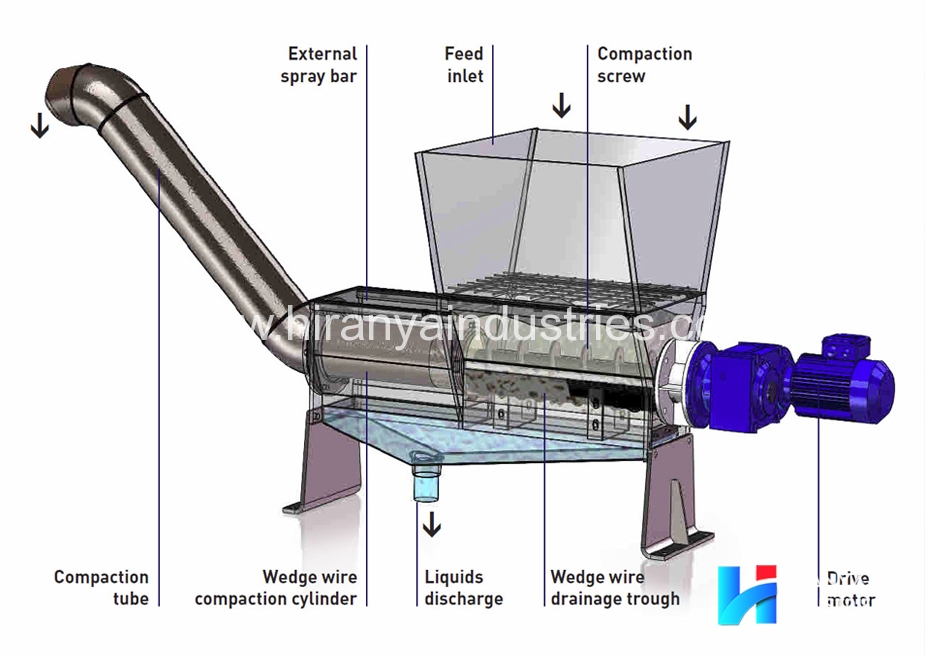

Dewatering Screw Press, Screw Presses, Dewatering Press Manufacturer

We are manufacturing Dewatering Screw Press for several applications over a period of three decades. Hiranya dewatering products have gained reputation for its quality & efficiency. Our supply & installations of machinery supplemented by our quality services which gained us a 100% customer satisfaction.

Product design is configured to suit the particular materials to be processed. We always take care of international advances in technology to help our customer to get the best of the time which we had expertise over years of experience. Thus the product ensures optimum performance and customer satisfaction.

Screw presses are used to dewater materials of different consistencies.

The use or objective of dewatering screw press varies according to the material:

- Improve the material behavior for further processing

- Improve storage life of the material

- Reduce weight or volume which in turns reduce transportation

- Increase gross calorific value

The method of functioning

The material is fed to the pressing screw through a feed hopper, and the pressing screw conveys it into the compression area, where the product is further compressed during onward transportation. This achieves reducing the volume in the screw flights of the press. At the end of the compression area, the product leaves the press through the discharge hopper. Screw presses are driven by mechanical or hydraulic systems with infinitely variable speed or electronic control.

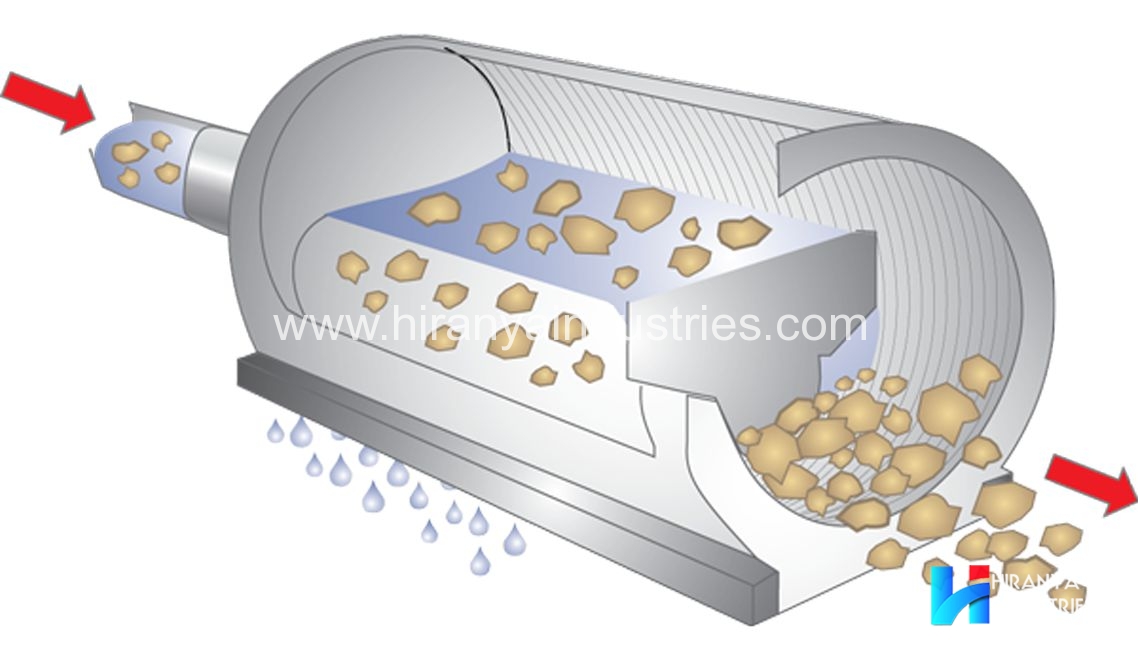

Sewage

The Hiranya Industries wedge wire Rotary drum screen is a suitable for fine screening of sewage and industrial effluent. It is the ideal solution for large applications requiring fine screens with openings as fine as 1 mm and no carryover. This equipment is available in a wide range of hydraulic and separation capacities to allow customizing for the most effective solution for your application. Rotary sewage drums in industrial applications or municipal wastewaters where they sometimes operate at near nominal flow capacity due to high fiber concentration in the solids load. These fibers agglomerate and absorb grease as they tumble towards the discharge end of the drum screen, cleaning the openings, allowing liquid to drain, and enhancing the effectiveness of the rotary screen’s dual spray wash system.

Product Highlights of the Horizontal Drum Screen:

- 304 or 316 stainless steel

- 0.5mm to 5mm wedge wire screen

- Larger screen field area than conventional for in-channel drum screen

- Horizontal drum screen

- No carry-over

- Integrated screw conveyor/compactor

- No mechanical serviceable parts in effluent process stream

- Dual spray screen washer system

Strainer Wedge Wire Screen

Hiranya Industries manufacturing strainer wedge wire screen in many types of strainer like a Basket stainer , Tee stainer , Y stainer , Duplex stainer , Conical strainers and automatic self cleaning stainer . We are also manufacture strainers complete set with housing as per party requirement . We provide complete engineering capabilities featuring in house design CAD service and 3D product models allow us to design your system. We are hands on company with the philosophy of striving to exceed our customer’s expectations in competitiveness, quality and service. Always working harder to serve you better.

Dewatering Screens

We will update soon..!!

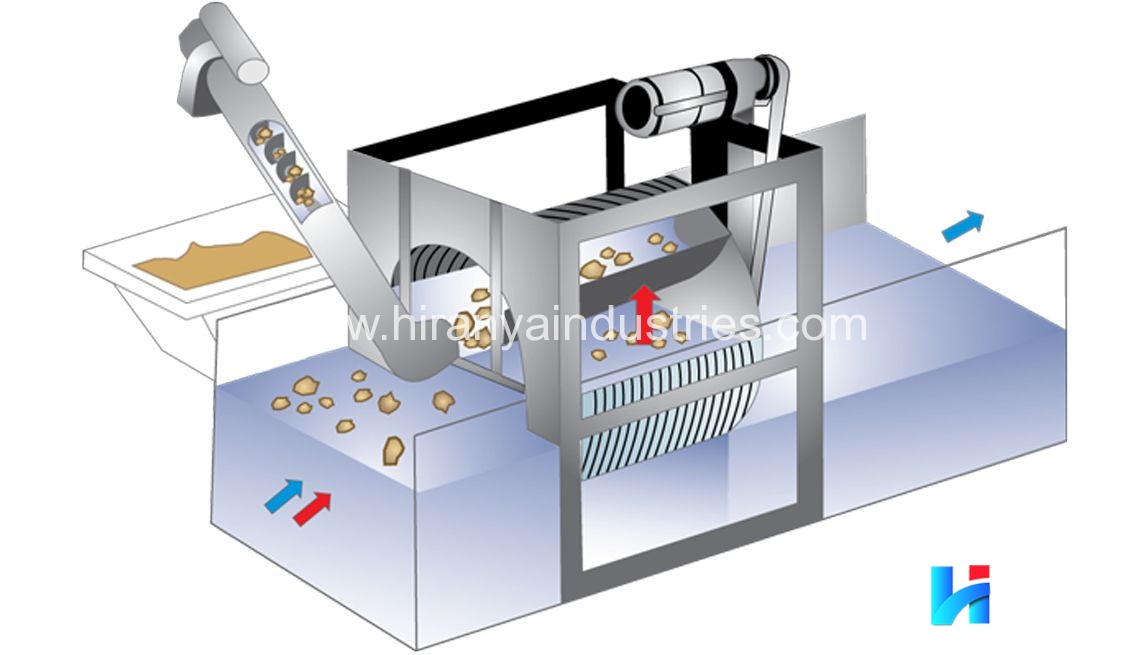

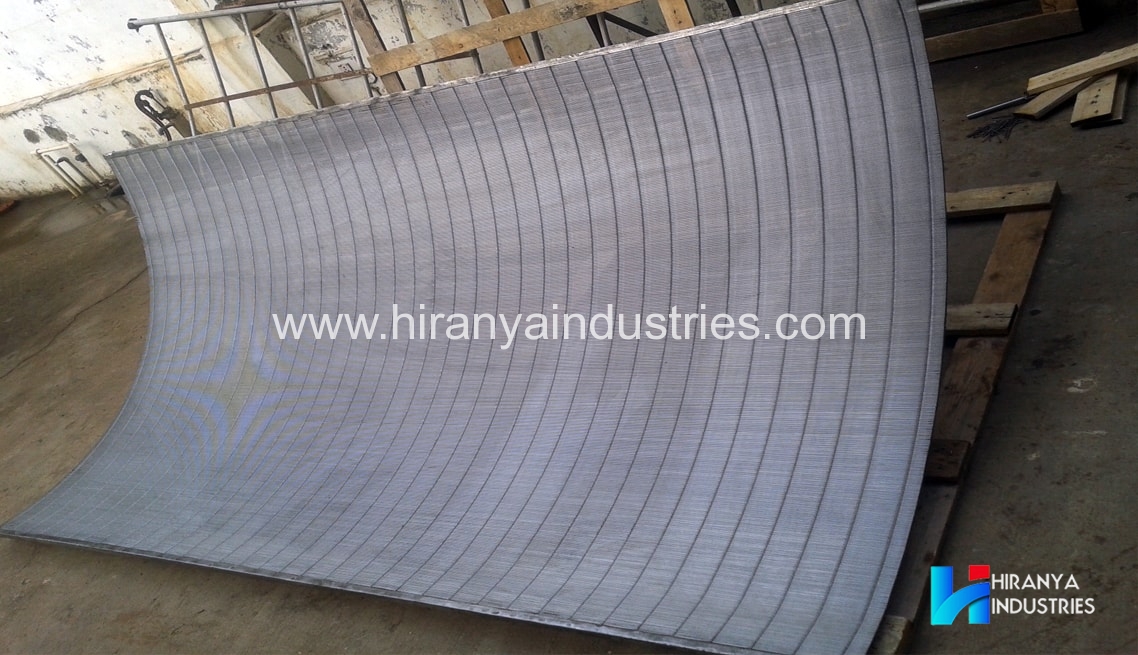

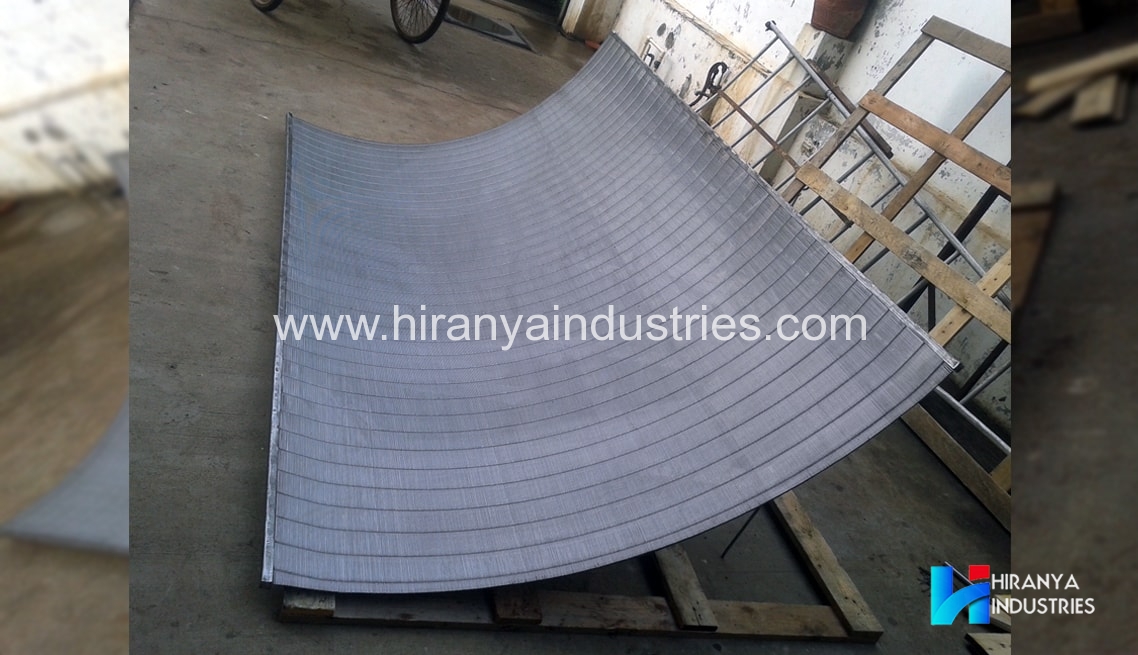

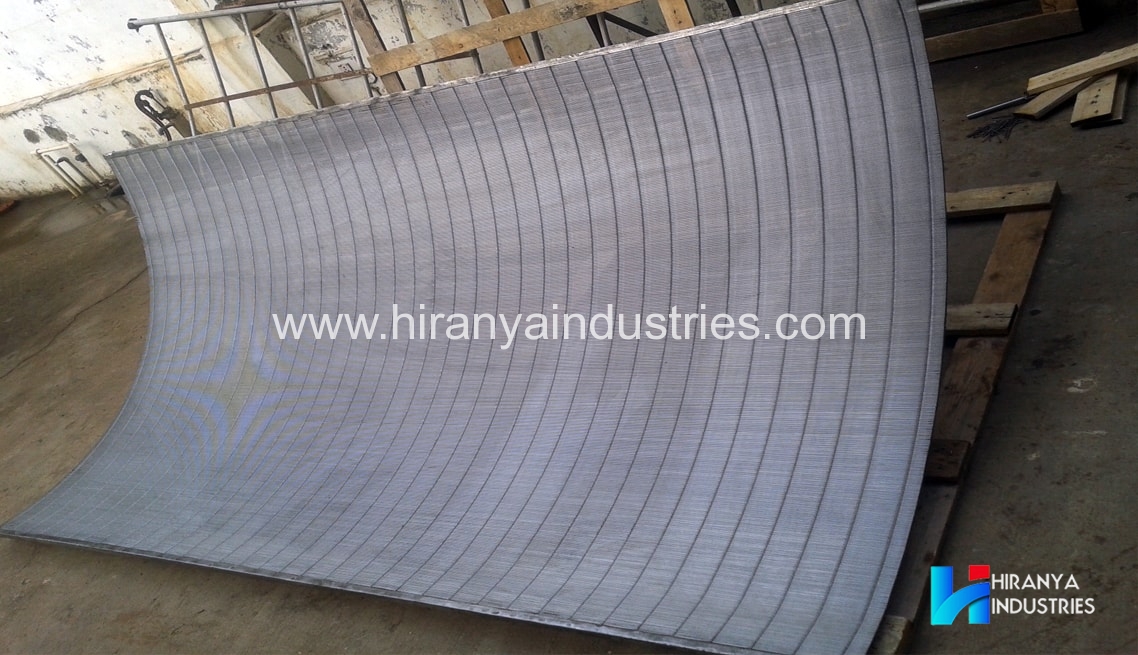

Run Down Screens / Hydraulic Screen / Parabolic Screen / DSM Screens

Hiranya Wedge Wire screens has developed run down screens (D.S.M. type) complete with box and curved wedge wire screens to suit particulars requirements of the customer and application to enable e relatively low cost solution for separating solid and liquids in sugar, paper and pulp, water treatment and chemical industry.

Features & Benefits

- High capacity

- Non clogging

- Permanent Screen Media

- No moving parts

- Little space needed

- Low equipment and installation costs

- Low maintenance costs

- Insensitive to changes in consistency or freeness

- Operating flexibility due to adjustable slice

- Easy maintenance and low cost

- Easy removal of solids through back flushing

- Longer service life

- Separation of liquid and solid waste for recycling

- Stainless steel material prevents corrosion

With no moving parts, these screens require minimal maintenance. Hiranya Industries carries a full line of gravity-fed DSM Screens available in the following types: 45°, 60°, 120°, 270°, 300°, and rapifine. They are often used in the following industries: mineral processing, chemical, food and pulp & paper.

Each of these screen sizes has been tailored for a variety of process applications. For example, the 45° DSM screen is best suited for thickening and screening, whereas the 120° type DSM Screen is capable of thickening pulp, recovering fiber, or separating fiber as small as 100 microns in length from a water suspension. It is very compact and requires minimal maintenance.

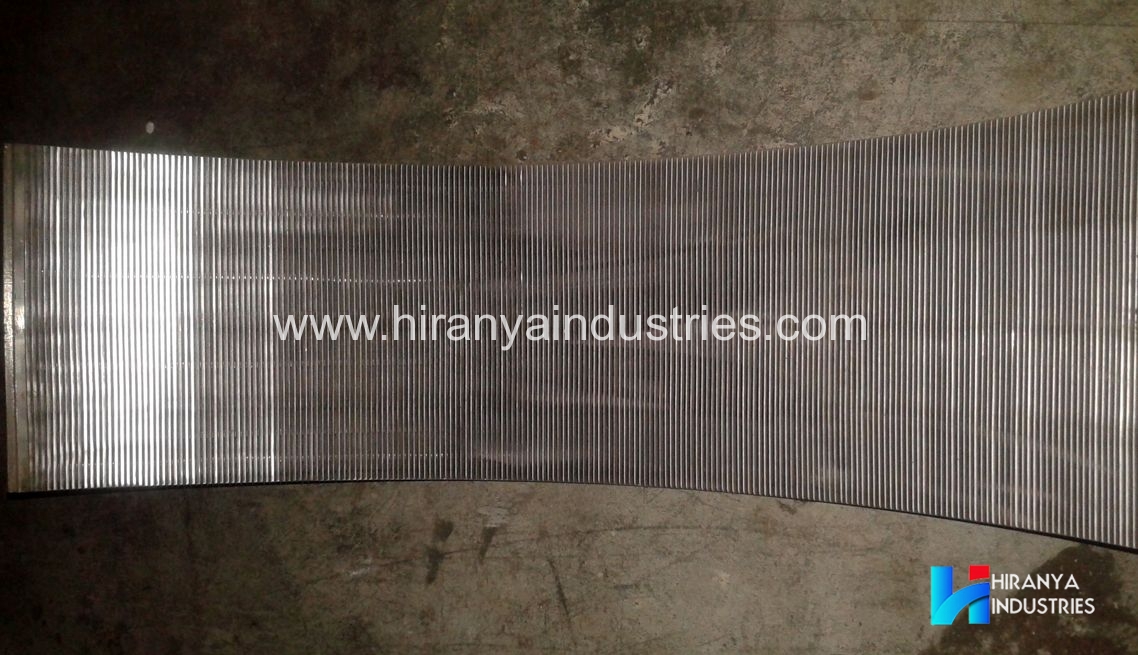

The DSM’s unique screen plate is made of wedge bars forming a bowed surface with horizontal slots between the bars. Normal slot width is 100 or 150 microns.

The flow to be screened is fed through a low pressure nozzle which distributes the flow tangentially over the full screen width by means of an adjustable slice that optimizes feed velocity. As the suspension flows along the screen plate, thin layers of water are ”sliced off” by the screen bars and pass through the slots together with fine particles.

Curved Screens / Sieve Bends & Cylinders

In addition to flat panels, wedge wires can be readily made up into full cylinders and segments of cylinders in most cases, the cross rode lie along the circumference and the profile wires lie parallel to the axis. Occasionally, this arrangement is reversed.